Company Activity

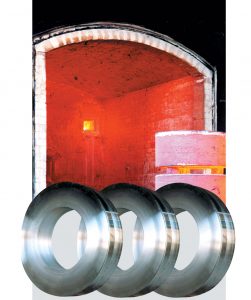

The main activity of Iran Ghaltak Company is the production of cast iron and steel rollers, rollics, and ring sleeves with different chemical analyses and different mechanical properties, billet and sponge iron, and repair and rebuilding services of all types of rollers.

Also, the design and construction of rolling racks and induction melting furnaces are carried out in this complex.

History of Iran Gholtak Company

Iran Gholtak Company was put into operation in 1375 with an annual capacity of 3,000 tons of steel and cast iron products, with the aim of supporting and supplying rollers for rolling industries, especially steel products, in Kashan city, desert industrial zone, and currently we have a production capacity of 8,000 tons of rollers. Until 1990, this company was under the supervision of Ghaem Reza Industries and Persia Metals Spadana holdings, and after that it was completely handed over to the private sector under the ownership of Mr. Engineer Reza Shahrashtani. The task of the early years of the activity was to meet the needs of domestic consumption, obtain new production technology and improve the performance of the products, and then export, which is currently ongoing and is being pursued. Also, after handing over the company to the private sector, the development plan of the company for the production of sponge iron by the tunnel method was keyed and more than 70% of the physical progress has been achieved, which we hope will be put into operation in the second half of this year in the first phase with the production of 50,000 tons and in The third phase will produce 200,000 tons.

The products of this company are generally used in the rolling industries of steel, aluminum, copper, food, lubrication, and rubber industries. Some products are cast by centrifugal method and some by gravity method in sand or metal molds. The material of the parts is from the group of iron alloys, which are low-alloy high-carbon steels and alloy ductile irons. Steels such as graphite steel, base steel, as well as cast irons such as acicular, alloy cast iron are among the most important alloy items. Some parts are also produced in two types. In other words, part of the piece is rich in alloy elements and another part is poor in alloy elements such as chromium, molybdenum, nickel, etc. are produced In addition to economic goals, this issue provides the coexistence of two mechanical properties to the maximum extent possible. Crispness in the working part of the roller and flexibility in the arm part of the rollers.

Type of order and services that can be provided

Custom registration system prevents mass production. Therefore, after announcing the customer’s need, the

production feasibility parts are placed first, and after approval, the technical-commercial offer is announced and finally it leads to a contract. Also, if needed, a visit is made to the place of consumption of the part. Therefore, each piece will have a unique production technology according to its workplace. Therefore, the rollers are guaranteed up to the nominal capacity. This issue is independent of time and sometimes two years after the delivery of the part may be included in the warranty. In some cases, an invoice is issued according to the performance of each part, and for example, if a part with a nominal capacity of 1000 tons per year is delivered to the customer and the part is not used due to the reduction in the diameter of the working place, and it has produced a maximum of 800 tons of product, 80% of the issued invoice amount is collected. This importance is mentioned in all contracts. In order to decide on the mentioned cases, upon the occurrence of an accident, the company’s experts will be dispatched as soon as possible to conduct a field visit to the existing cases and make an appropriate decision .

Technology improvement

Improving the technology of heavy rollers, formulating the technology of molds required by the collection using simulation software of the casting process has been among the obvious cases of technology. Participating in the Steel Symposium, participating in the IMAT seminar and winning the title of the best article are among the other activities of this company in recent years. Currently, we are preparing and writing a book on the production of rollers.